Recently the EPA proposed to place limits on the carbon pollution from new fossil fuel power plants, which would be required not only to capture some of the carbon dioxide produced, but also to produce a smaller amount in the first place.

The regulations include:

• Coal plants having a 500 kg per megawatt hour of producing power limit on carbon dioxide pollution.

• Natural gas plants limitations of just over 450 kg per megawatt hour of pollution of carbon dioxide.

Opposition to this was expected to be strong, with companies stating that implementation of these regulations would not be commercially feasible. The first version of the rules alone received a staggering 2.5 million comments before removal to address procedural issues.

Some experts believe that these new rules could help the U.S. economy progress to a low carbon future, and with the slow integration over 7 years of these standards that this was very do-able.

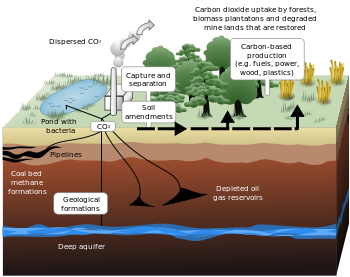

An additional flexibility that the EPA stated would be that plants would have to collect a portion of their carbon pollution. While advocates in the industry have argued that this change will be necessary for fighting climate change, the research and development is still in a very early stage.

On top of this, the power industry is shifting towards natural gas to generate electricity, which could mean that the market for plants with included carbon-capture equipment could be as far as decades away.